Stable Micro Systems - Solving strength and stickiness in low-salt bakery products

According to the World Health Organization (WHO), adult salt intake of less than five grams per day can help to reduce blood pressure and the risk of cardiovascular disease.

According to the World Health Organization (WHO), adult salt intake of less than five grams per day can help to reduce blood pressure and the risk of cardiovascular disease.

In response, WHO member states have pledged to reduce the global population's intake by a relative 30% by 2025. As such, low-salt launches are rife in the market. Yet, while health authorities worldwide agree too much salt can be bad for health, it does have an important role in texture – particularly in baked goods, in which it plays a multitude of textural roles.

Consensus Action on Salt and Health (CASH) published a report1 in 2018 that revealed bread is responsible for up to 15% of daily salt intake, making baked foods a clear opportunity for salt reduction reformulation in many western markets. However, salt is pivotal to dough strength and stickiness. Stickiness, is important at the mixing, dividing and rounding stage. A dough that is too sticky does not leave the mixer or rounder properly. If, on the other hand, a dough is not sticky enough, it is not formed properly by the rounder and the resulting product does not have the desired crumb structure. An appropriate level of stickiness is also needed during the sheeting and moulding step to help hold the folded layers of dough together and ensure consistency of aeration in the final baked product. Several other factors such as overworking, addition of excess water, flour extraction, amount of water-soluble pentosans, differences in protein composition and enzyme imbalances can give rise to such a problem.

Bakers have to tread a fine line: excessive stickiness causes processing difficulties and many hours of 'down time' if not controlled. However, if cutting salt content also leads to a weakening of the dough, problems of a different nature, but equal importance, become evident. To gauge the impact of a salt reduction programme on dough quality, samples should be prepared and tested prior to bulk preparation to identify the ideal formulation and/or predict necessary processing changes.

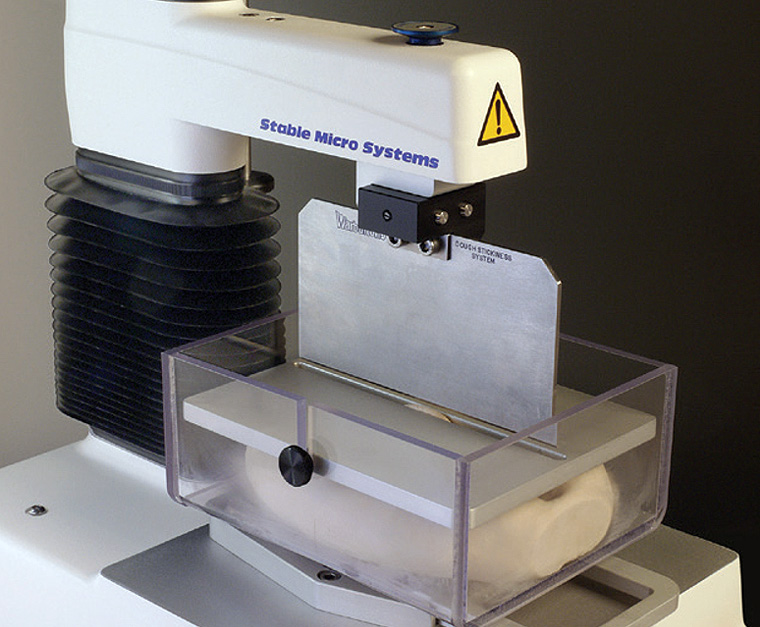

Figure 1: Warburtons Dough Stickiness System

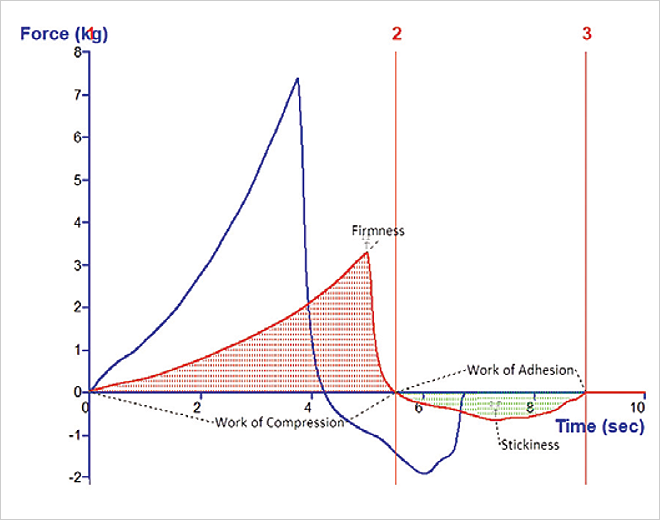

The Warburtons Dough Stickiness System (Figure 1) provides a means of quantification by placing a retaining plate on top of a 500g/1000g dough piece (taken straight from the line) which applies a slight pressure. A narrow blade is driven through a slot in the plate, to a defined distance - obtaining the compression peak and area of the dough, giving an indication of dough strength. As the blade is withdrawn, Exponent software calculates the adhesion peak and area, with a higher peak/area associated with a stickier dough. Comparing the results of a low-salt dough with a dough containing regular levels of salt can give a good indication of the effects of salt reduction (Figure 2).

Figure 2: Graph comparing two types of dough formulation and their effect on firmness and stickiness parameters

Additionally, salt tightens the gluten structure and helps loaves retain the carbon dioxide gas formed during fermentation. This has a great impact on volume after baking which is an important quality indicator. As a result, lowering salt content can lead to smaller, less attractive breads thereby reducing desirability for consumers. Using instruments such as Stable Micro Systems' VolScan Profiler (Figure 3) can help to provide quantifiable volume and density measurement and, again, can be used as a comparative tool during reformulation. The Volscan Profiler works by mounting a bakery product at a suitable supporting location, and the sample is automatically weighed. A laser then measures the contours of the product at given intervals as it rotates and provides manufacturers with a non-contact operational assessment with the results available in less than 60 seconds. Product volume, density and a full dimensional profile (e.g. height, length and width) are instantly archived and can be viewed in 2D or 3D to allow visual interpretation alongside comparison of the results.

Figure 3: Volscan Profiler

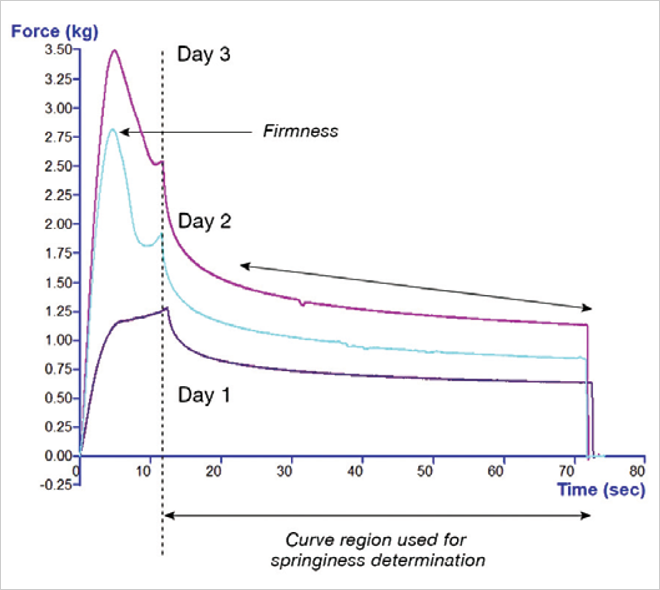

As well as impacting the texture of fresh bread as it hits the shelf, salt also has an effect further along the line. Traditionally used as a preservative, salt is paramount in extending shelf life as the water it attracts can help keep bread from staling too quickly in a dry environment. Measuring the firmness and springiness (elastic recovery) of reduced-salt bread over an extended period of time, in different conditions and then comparing with other formulations is key to discovering how quality of the bread may be affected over time (see Figure 4 for typical curves).

Figure 4: Graph highlighting the increase of firmness and decrease of springiness as shelf life increases

This type of measurement can be made by performing a compression test where a compression distance is held for a chosen period of time, over which the product's recovery is recorded. A simple calculation can be made to analyse the data which can be used to indicate staleness. A major change during the ageing of bread/cake is an increased resistance to compression (firming) and a loss of recovery when compressed, i.e. decreased springiness. Studies of this rheological change may prove beneficial in obtaining a better understanding of the staling process and how it is affected as a result of formulation changes such as lowering salt content.

1. Public Health England. Salt targets 2017: Progress report. 2018

2882