Mettler Toledo - Improve quality and productivity with the latest metal detection innovations

Product inspection equipment is a necessity for most bakeries and food processors. Having equipment such as metal detectors on a production line supports compliance with GFSI-based food safety standards and retailer codes of practice, and ensures product quality and consumer safety.

Product inspection equipment is a necessity for most bakeries and food processors. Having equipment such as metal detectors on a production line supports compliance with GFSI-based food safety standards and retailer codes of practice, and ensures product quality and consumer safety.

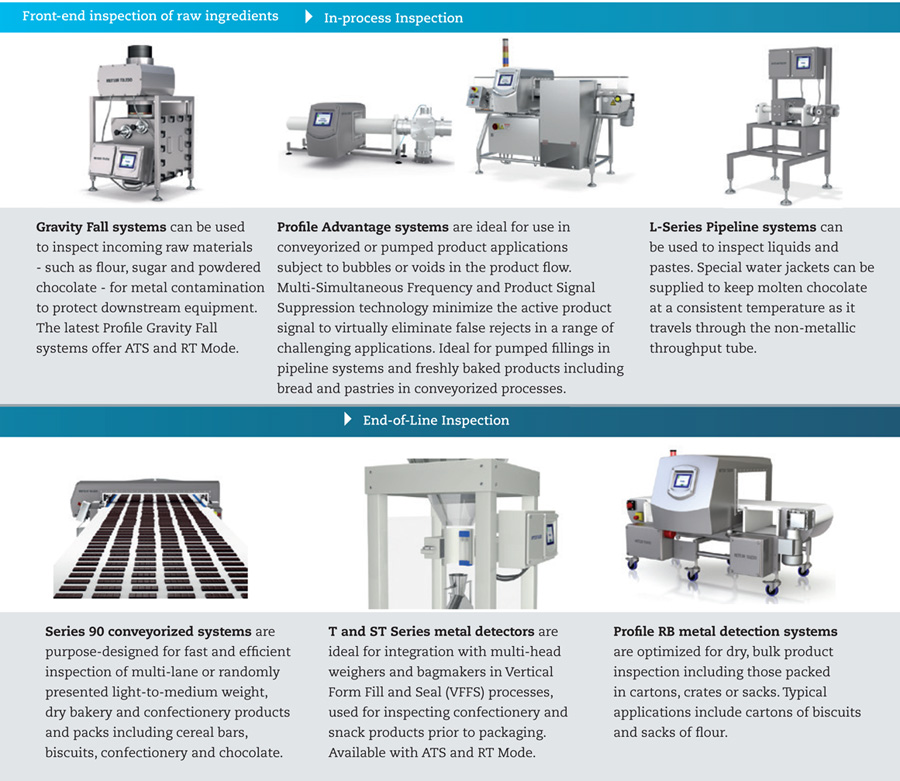

Metal detectors are used to identify fragments of ferrous, non-ferrous and stainless steel metals that can enter the baking process. This might be from external sources in raw ingredients, or be introduced during the baking process, e.g. from a broken blade when slicing bread. METTLER TOLEDO offers a wide range of high performance metal detection solutions that can be installed at various critical control points (CCPs).

The latest Gravity Fall metal detection systems from METTLER TOLEDO are available with ATS and RT Mode testing solutions

How well is your metal detector performing?

You need to ensure your metal detectors are working correctly in order to deliver compliance and safety assurances, and produce consistently high quality products. Confidence in system performance is gained through conducting regular performance monitoring tests - essential for compliance with GFSI-based standards and retailer codes of practice.

However testing often involves stopping production or wasting good product, both of which can have a negative impact on overall equipment effectiveness (OEE).

One challenge you may face when using Gravity Fall systems and Throat metal detectors is accurately confirming centreline (worst-case) sensitivity of your metal detectors. Without that confirmation, you cannot be sure you are reliably protecting your customers and your brand.

Additionally, every time a test is carried out, there can be an impact on productivity and labour costs. Tests often require a stop in production for multiple minutes, and two operators are often required to physically carry out the tests.

The higher the frequency of testing, the bigger the impact it has on productivity and profitability, and the larger the volume of associated product waste.

How the latest metal detection innovations make routine testing easier

Innovative metal detector testing solutions such Automatic Test System (ATS) and Reduced Test (RT) Mode are designed to improve the accuracy of tests, decrease the time it takes to carry out the tests and reduce the frequency of testing required.

Innovative metal detector testing solutions such Automatic Test System (ATS) and Reduced Test (RT) Mode are designed to improve the accuracy of tests, decrease the time it takes to carry out the tests and reduce the frequency of testing required.

Award-winning and approved by a major UK retailer, ATS is a non-invasive method of testing recently launched by METTLER TOLEDO. It is the only method that can confirm centreline sensitivity to ensure maximum brand protection.

METTLER TOLEDO's innovative RT Mode feature uses intelligent software to continuously check the performance of the metal detector to ensure it is always working to, or better than, your specification.

RT Mode ensures the metal detector is always functioning correctly, and alerts operators to any status changes that may lead to a drop in performance before the metal detector goes out of specification.

Mike Bradley, product inspection specialist at METTLER TOLEDO explains how these benefits can affect food processors: "One of our customers used to test every two hours before introducing RT Mode. They have now reduced testing to every 12 hours. They are reaping the benefits of increased productivity and labour efficiencies, as well as reduced product waste."

Drivers for change

Bradley continues, "Productivity and product quality are two of the key drivers for our customers, alongside cost reduction. If a business can reduce costs and increase operator efficiency to allow them to carry out more production-related functions, rather than test functions, there is a direct correlation with profitability. Our latest innovations as a whole deliver cost-down, productivity-up benefits, whilst ensuring maximum product quality and brand protection, aligning with the main business priorities of our customers."

A range of metal detection solutions to meet customer needs

Depending on the application, you may need to inspect products for metal contamination at a variety of CCPs:

- - At the front-end, including raw ingredients prior to processing

- - In-process inspection

- - At end-of-line – either single or multi-packs of finished goods

Whatever the CCP, product inspection specialist METTLER TOLEDO has a solution. See more at www.mt.com/md-ats

3462