BETTER PERFORMANCE WITHOUT PRESSURE

BETTER PERFORMANCE WITHOUT PRESSURE

Written by: Patrick Duss (Mr. Vacuum) (pictured)

The application of vacuum technology in the bakery production process has much more to offer than is often assumed. The Vacuum Cooling & Baking Academy wants its participants to experience this technology in a series of two-day master classes starting this autumn.

After the vacuum cooling technique was once used for the rapid re- cooling of 'fresh' products such as flowers, vegetables and turf, where the main effect was to increase their shelf life, it eventually made its appearance in the bakery market. In contrast to the method used for the aforementioned product categories, the technology was not only used for rapid cooling after baking, but earlier – during the baking process – enabling more optimal control of the end product to be created. This integration is unique in the vacuum cooling sector and reason enough to extend the international term Vacuum Cooling to Vacuum Cooling & Baking.

After the vacuum cooling technique was once used for the rapid re- cooling of 'fresh' products such as flowers, vegetables and turf, where the main effect was to increase their shelf life, it eventually made its appearance in the bakery market. In contrast to the method used for the aforementioned product categories, the technology was not only used for rapid cooling after baking, but earlier – during the baking process – enabling more optimal control of the end product to be created. This integration is unique in the vacuum cooling sector and reason enough to extend the international term Vacuum Cooling to Vacuum Cooling & Baking.

Pandora's box

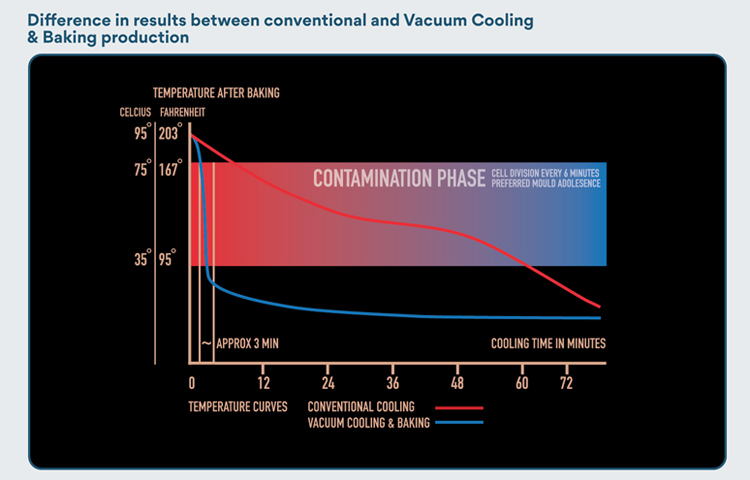

By lowering the air pressure via a curve specific to the product, the boiling point is lowered to just a few degrees. This creates an integration of the cooking and cooling processes, as it were, and offers optimum control to produce a perfect production. For example, stability, volume, moisture distribution as well as the crust and crumb structure can be controlled with the contamination period being minimised. The result of a product after the expert application of Vacuum Cooling & Baking? A better product in many ways, with a longer shelf life in a shorter production time. It sounds like Pandora's box, but the optimal result requires insight into the influencing factors that determine the result.

Third Dimension

With the launch of the Vacuum Cooling & Baking Academy in September of this year, the organisation wants to provide more insight into the 'third dimension' of this technology and thus dispelling many of the existing prejudices and misunderstandings regarding its application in the bakery. It can be likened to an iceberg; what can be seen at first sight only represents a small part of what is really going on under the surface. 'Optimal results require not only an understanding of the baking process but also the application of a sophisticated curve-control technique. The third dimension is added by technological knowledge of the vacuum process. Thus, there is not only vacuum cooling, but also vacuum baking, which, if all elements are carefully coordinated, leads to astounding advantages and product improvements.

"The third dimension is added by technological knowledge of the vacuum process."

"There is not only vacuum cooling, but also vacuum baking."

Sharing specialist knowledge

The Verhoeven Bakery Equipment Family, organiser of this Academy, has specialists in all three segments who are keen to share their knowledge with interested parties from the bakery sector. With more than half a century of experience in machine construction and the logistics of production processes and several decades of specialisation in the bakery business, master bakers and engineers have worked on numerous, innovative customised solutions for bakeries all over the world. The specialist divisions BVT and Newcap form the family, together with the packaging specialist Bakepack and Vacuum Cooling & Baking Solutions. BVT, fully named BVT Dough Process Solutions, specialises in the development and production of customised laminating and dough band processing lines. The sister company Newcap Industrial Handling Solutions, focuses, as the name suggests, on the development and production of customised handling solutions for the bakery industry. Finally, Bakepack integrates packaging solutions into the total production line, offering innovative, sustainable solutions that support the total production process. With the arrival of several international specialists, including the renowned Swiss vacuum cooling pioneer Patrick Duss, who is also known as "Mr. Vacuum", a speciality has been built up over the past few years that has made the company the world market leader for Vacuum Cooling & Baking in the bakery sector.

Worldwide, the Verhoeven Bakery Equipment Family has been able to add and integrate its specialised knowledge and technology into large industrial bakeries, as well as at in artisan bakeries.

The broad experience and intense collaboration between the bakery specialists and the engineers, has given the company a strong growth impulse over the years. By adding the knowledge of vacuum technology to these specialisations, the aforementioned third dimension has been created ballooning the company's image as an innovative frontrunner.

During the Academy sessions, all the important elements will be considered and, during a number of workshops, the participants will be able to experience for themselves how Vacuum Cooling & Baking contributes to a qualitative improvement of the field.

The participants receive a comprehensive syllabus of the material covered and are given answers to questions, such as:

- - How does Vacuum Cooling & Baking work? What is needed and what are the benefits? How are the machines developed and what requirements do they have to meet?)

- - What is needed to work qualitatively and safely and achieve the best results?

- - With which products do I achieve desired results with this technology?

- - What economic advantages do I gain by integrating Vacuum Cooling & Baking?

Vacuum technology: wandering in space?

The concept of a vacuum is certainly not new. Physical experiments with the phenomenon were carried out centuries’ ago. The application in daily use, in science, healthcare and industry has been given an extra boost by space travel and its resulting research. The application of vacuum technology to the baking process has some similarities with space travel. When, after the launch of the rocket - which involves a great deal of energy and heat – the spacecraft leaves the atmosphere and enters an environment without gravity, all the laws change. Enormous speeds can be achieved, but without guidance and direction it would become adrift in space. When the baking process has started and, after heating, the products are brought into an environment where the air pressure is removed, the comparison with the launch of such a spacecraft comes to mind. Here, too, many of the principles of traditional baking production change. If the vacuum system takes over control from the oven during the baking process, the optimum end product can be created. Volume, moisture and stability are precisely controlled during an accelerated cooling process. But here too, as in space, the same applies: provided the right route is followed and the equipment is controlled with knowledge.

Readers may be reassured that you will not need space suits!

Vacuum Cooling & Baking Academy

In 2021, 3 two-day master classes are planned on the following dates:

- - Thursday 23 / Friday 24 September

- - Thursday 7/ Friday 8 October

- - Thursday 25 / 26 November

Interested parties can request more information or register for one of the Master Classes via info@vacuumcooling.com

The Vacuum Cooling & Baking Academy comprises a full two-day programme including meals and overnight stays. The master classes take place in the Academy Room and Tasting Bakery of Verhoeven Bakery Equipment Family, Parallelweg 13, 5349 AD Oss

Knowledge as a basis for the Academy is supported by the family members:

Verhoeven Bakery Equipment Family, (bakery branch of Verhoeven Family of Companies) BVT Dough Process Solutions

Newcap Industrial Handling Solutions

Vacuum Cooling & Baking Solutions

Bakepack End of Line Solutions