Page 50 - Baking Europe Journal - Winter 2022

P. 50

ENERGY

50 HYDROGEN

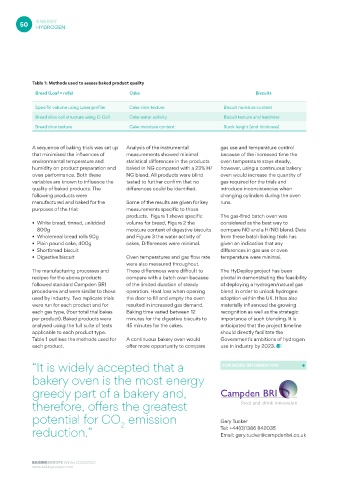

Table 1: Methods used to assess baked product quality

Bread (Loaf + rolls) Cake Biscuits

Specifi c volume using Laser profi ler Cake slice texture Biscuit moisture content

Bread slice cell structure using C-Cell Cake water activity Biscuit texture and hardness

Bread slice texture Cake moisture content Stack height (and thickness)

A sequence of baking trials was set up Analysis of the instrumental gas use and temperature control

that minimised the infl uences of measurements showed minimal because of the increased time the

environmental temperature and statistical diff erences in the products oven temperature stays steady,

humidity on product preparation and baked in NG compared with a 23% H/ however, using a continuous bakery

oven performance. Both these NG blend. All products were blind oven would increase the quantity of

variables are known to infl uence the tasted to further confi rm that no gas required for the trials and

quality of baked products. The diff erences could be identifi ed. introduce inconsistencies when

following products were changing cylinders during the oven

manufactured and baked for the Some of the results are given for key runs.

purposes of the trial: measurements specifi c to those

products. Figure 1 shows specifi c The gas-fi red batch oven was

• White bread, tinned, unlidded volume for bread, Figure 2 the considered as the best way to

800g moisture content of digestive biscuits compare NG and a H/NG blend. Data

• Wholemeal bread rolls 90g and Figure 3 the water activity of from these batch baking trials has

• Plain pound cake, 400g cakes. Diff erences were minimal. given an indication that any

• Shortbread biscuit diff erences in gas use or oven

• Digestive biscuit Oven temperatures and gas fl ow rate temperature were minimal.

were also measured throughout.

The manufacturing processes and These diff erences were diffi cult to The HyDeploy project has been

recipes for the above products compare with a batch oven because pivotal in demonstrating the feasibility

followed standard Campden BRI of the limited duration of steady of deploying a hydrogen/natural gas

procedures and were similar to those operation. Heat loss when opening blend in order to unlock hydrogen

used by industry. Two replicate trials the door to fi ll and empty the oven adoption within the UK. It has also

were run for each product and for resulted in increased gas demand. materially infl uenced the growing

each gas type, (four total trial bakes Baking time varied between 12 recognition as well as the strategic

per product). Baked products were minutes for the digestive biscuits to importance of such blending. It is

analysed using the full suite of tests 45 minutes for the cakes. anticipated that the project timeline

applicable to each product type. should directly facilitate the

Table 1 outlines the methods used for A continuous bakery oven would Government’s ambitions of hydrogen

each product. off er more opportunity to compare use in industry by 2023.

“It is widely accepted that a FOR MORE INFORMATION →

bakery oven is the most energy

greedy part of a bakery and, Campden BRI

Campden

therefore, off ers the greatest f f food ood and drink innovation

potential for CO emission Gary Tucker

2

reduction.” Tel: +44(0)1386 842035

Email: gary.tucker@campdenbri.co.uk

BAKINGEUROPE Winter 2022/2023

www.bakingeurope.com