Consumer behaviour fluctuates widely and can no longer be assessed as accurately as it was possible a few years ago. These fluctuations also affect dough production, which will have to become much more flexible in the future. AGVs (Automated guided vehicles) offer interesting and cost-effective solutions here.

Consumer behaviour fluctuates widely and can no longer be assessed as accurately as it was possible a few years ago. These fluctuations also affect dough production, which will have to become much more flexible in the future. AGVs (Automated guided vehicles) offer interesting and cost-effective solutions here.

The classic approach to dough production and resting has proven itself for many years. The AGV mixing bowls-including-carriage move quickly and reliably in a fixed arrangement. For this purpose, the room concept is tailored to the customer. Provided the correct design has been chosen, automatic and efficient dough making and resting systems like this will provide many years of service.

But how do you deal with new customer requirements?

It is already evident that the markets are changing and it is becoming increasingly difficult for large bakeries to react to volatility and uncertainties particularly as current systems are usually designed to operate for between 15 to 20 years. It is true that classic room concepts can also be adapted later, but only with considerable effort and at great expense.

New ideas are, therefore, needed so that bakeries can continue to work economically in the future. This is where spatial concepts with AGVs come into play. They enable highly flexible, automated dough production.

New ideas are, therefore, needed so that bakeries can continue to work economically in the future. This is where spatial concepts with AGVs come into play. They enable highly flexible, automated dough production.

Proven technology for innovative concepts

AGVs have been used successfully for many years in a wide variety of industries, such as automotive builders or in the intralogistics of many bakeries. As a result, they have been continuously optimised in areas such as battery life, charging, speed, durability, etc., so that proven systems are now available. The idea: AGVs navigate independently in space and bring raw materials, bowls and dough resting boxes to the desired location with high precision and efficiency within defined work processes. For this purpose, floorbound automated guided vehicles are equipped with the latest navigation systems and sensor technology. The big advantage: they are battery-operated and do not require rails or induction loops, which means that the routes and thus the production processes can be changed manually at any time. In this way, the typical FIFO (First- In-First-Out) process is dispensed with. Furthermore, all DIOSNA machines can be integrated into an AGV concept. If necessary, the AGVs can also interact with several systems via a communication interface, as well as with their stations and a fleet management system. The latter is based on the DIOSNA production software, the Bowl Manager, which has been tried and tested for many years.

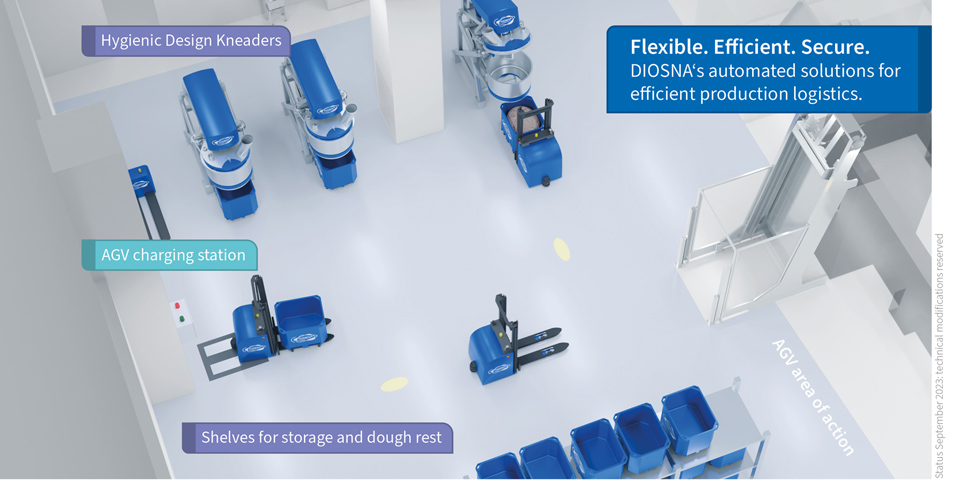

Automated solutions with low-lift and high-lift AGVs

Room concepts from a new perspective

One of the greatest advantages of using an AGV is its great flexibility in dough production and the ability to adapt room concepts easily to current requiremants. Process steps such as dosing, kneading, resting and tipping become independent of location. As a result, not only is capacity expansion possible at any time, but the operators become much more flexible in designing the processes. DIOSNA offers two different AGV solutions - both will go into operation at the start of the new year in two different, large bakeries:

- - AGVs with low-lift function move the stainless-steel bowls or dough resting containers at ground level and deliver them to their processing location.

- - AGVs with high-lift function move the stainless-steel bowls or dough resting containers both horizontally and vertically. This enables multi-level bowl storage on shelves thereby using considerably less space for the dough to rest.

AGV Layout example for dough production

Cleaning and repair – no downtime

Other key advantages:

The AGV’s versatile properties allow it to approach the dosing points to pick up the components, thus minimising the piping otherwise used for all raw materials, as well as for the technologically demanding pre-dough from a DIOSNA predough system. With the classic room concept, maintenance and cleaning is only possible during a production stop, whereas with AGV, the bowls can be cleaned in between process stages in a separate room.

An interesting spin-off: cleaning agents in production are avoided and the cleaning station does not have to be connected to the conveyor system.

In classic approaches, it is not uncommon for the entire line to be stopped in the event of problems. With AGVs, it is easier and quicker to exchange a bowl including carriage, even across several production lines.

System Structure: assembly and commissioning times are considerably shorter compared to those of a linear concept. Experts only require a quarter of the time that is now required for commissioning.

Pre-planning: DIOSNA's digital twin simulates all processes and routes in advance, so that there are no unpleasant surprises at the start of production.

Conclusion and Outlook

With the use of AGVs, dough production is raised to a new level: getting started is easy where you can enjoy greater system flexibility, a smaller footprint even for specially tailored requirements. Hybrid approach – if this is your preference, you can integrate a solution with or without AGV or you can opt for partial automation. Versatility and flexibility is the key.

Rest assured all AGVs are connected to the central fleet management system, so that the integration of other system parts, such as packaging or loading, can be seamlessly linked.

Are you coming to IBA?

Why not come and see the technology for yourself and get an insight into how easy it is to integrate AGVs into existing systems live at the iba 2023 in Munich.

Our team of experts will be happy to advise you in Hall A2, Stand 340 – DIOSNA looks forward to your visit.

Are you interested in bringing your production to the next level? Contact us for your free initial consultation.

Mr. Thorsten Iborg

Tel: +49 (541) 33104 773

Email: Thorsten.Iborg@diosna.de