Page 22 - Baking Europe Journal - Winter 2022

P. 22

TECHNOLOGY

22 AUTOMATION/AI

“Smart baking has the potential with the acceptance that some

disruption to existing working

to improve both output practices will have to be endured and

seen as an investment for the future

performance of the entire bakery whilst managing collateral damage to

existing working practices/

plant and its research and productivity that may occur during

development operations.” upgrade.

Key smart manufacturing

techniques for baking

smart baking system allows for Despite the availability of smart Here we drill down a little further into

process control which is based on processing equipment, uptake in the some of smart manufacturing

product properties, rather than industry continues to be slow with techniques and technologies:-

parameters such as temperature and technology readiness levels varying

relative humidity. and the reliability and robustness of 1. PAT technology-based sensing of

actual process conditions being in baking and baked products.

For example, the sensing technologies need of improvement. Integration • As described above, this is a major

presented below have the potential to with the company’s data constituent of smart baking, which

deliver real-time information on material management control systems and can record a wide variety of critical

and product properties enabling more decision support tools can also parameters for the baking process

informed adjustments in variations of present obstacles that prevent (Fig. 2).

raw materials instead of relying on upgrading. Finally, trust in new

off -line and laboratory analyses of technology is vital, requiring the • In particular, a PAT system carries

fi nished products. Signifi cant involvement of all relevant out an assessment of incoming

improvements in effi ciencies and management personnel in the ingredients, such as fl our, and

product quality can, therefore, be company to adopt a clear vision of reports chemical properties such as

enjoyed across the entire production the long-term benefi ts of moisture, protein and gluten

chain from plant to consumer. modernisation of this nature along content. It can also monitor

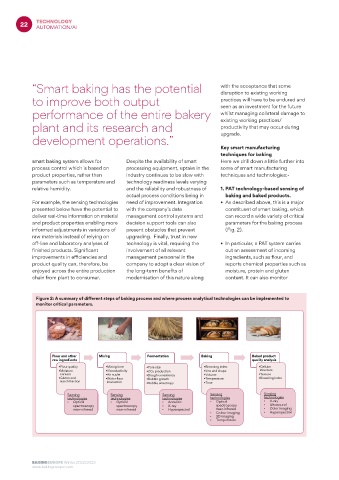

Figure 2: A summary of diff erent steps of baking process and where process analytical technologies can be implemented to

monitor critical parameters.

Flour and other Mixing Fermentation Baking Baked product

raw ingredients quality analysis

•Flour quality •Mixing time •Pore size •Browning index •Cellular

•Moisture •Viscoelasticity •CO 2 production •Size and shape structure

content •Air nuclei •Dough consistency •Volume •Texture

•Gluten and •Water flour •Bubble growth •Temperature •Browning index

starch fraction interaction •Bubble anisotropy •Time

Sensing Sensing Sensing Sensing Sensing

technologies technologies technologies technologies technologies

• Optical • Optical • Acoustic • Optical • X-ray

spectroscopy spectroscopy • X-ray spectroscopy • Ultrasound

near-infrared near-infrared • Hyperspectral near-infrared • Color imaging

• Colour imaging • Hyperspectral

• 3D imaging

• Temperature

BAKINGEUROPE Winter 2022/2023

www.bakingeurope.com